Performance Camshafts

- on June 13, 2021

- Categories: News and Resources

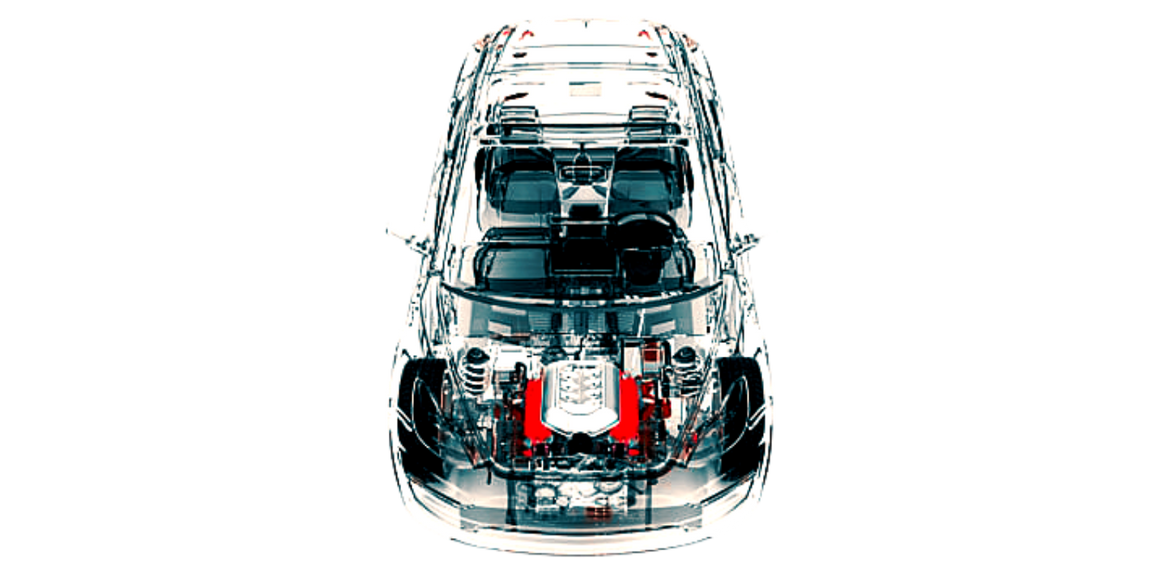

Camshafts are the central commanding unit of an engine. It plays an essential role in an internal combustion engine as they control the intake and exhaust valves that allow the combustion process to complete. Without them, there would be no combustion happening, and no combustion means no power, and the domino effect goes on.

The camshaft is a vital key to delivering and allowing the engine to proceed smoothly. They affect performance and efficiency; and how they contribute greatly to city driving and race days.

What are Camshafts?

Technically, it is a rod that rotates and slides to a piece of machinery to turn the rotational motion into linear motion, in this case, the radial cams. The cams are the special ridges attached across the rod-like miniature avocado-shaped sleeves that tap the intake or exhaust valves. The camshaft is then connected to the crankshaft, driven by either a belt, chain, or gears. This secures the synchronization and timing of the valves with the piston position that ranges from the top dead center (TDC) to the bottom dead center (BDC). The belts/chain/gears are also known as timing belts/chain/gear because they are responsible for that role. Camshafts in automobiles are made either from cast iron or steel and determine the RPM range of an engine powerband.

What makes a Performance Camshaft?

Construction of Camshafts

They are made from metal and are solid most of the time; though hollow camshafts are available, they are not that popular. With that, solid camshafts can be either: Cast-iron or Steel.Cast-Iron:

Cast-Iron Camshafts

Cast-iron camshafts are widely produced and outnumber steel ones. These camshafts have an excellent wear resistance due to the chilling process they undergo to harden them. Other elements are added to the iron prior to the casting to make it more suitable for its application.

Steel Camshafts

We did not say that cast-iron material is inferior to the steel ones, but when it comes to a high-quality camshaft, steel camshafts have the edge over them, for these camshafts are used and suitable for high-performance engines. However, this is far more expensive and deals a lot of time to process. It can be constructed by machining (using a metal lathe or milling machine), forging, casting, hydroforming, or gas nitriding.

What are ValveTrain Layouts?

Today we called them SOHC or DOHC - Single Overhead Camshaft and Double Overhead Camshaft. Early combustion engines use a cam-in-block layout, like the overhead valves, where the camshaft is situated close to the engine's bottom. Early flathead engines have the valves in the block, and the cam acts directly on the valves. In an overhead valve engine, the cam follower or lifter transfers its motion to the valves at the mounted engine via pushrod and a rocker arm lever.

Valvetrain layout is based according to the number of camshafts per cylinder bank. So to illustrate, a V6 engine with four camshafts (two per cylinder) is commonly addressed as a double overhead camshaft engine.

What Do Performance Camshafts Do?

Performance Characteristics

There are four ways camshafts affect our engines, including the duration, lift, timing, and lobe separation angle.

Duration

For the duration, it determines how long the intake and exhaust valves open measurement-wise. They play a significant role in producing the amount of engine power. Longer duration means increased power at a higher RPM range, but it makes less torque at a low RPM range.

Another effect of increased duration is the overlap, which determines the time that both of the valves are open. But don't be confused between duration and overlap; duration is measured in the distance (mm, inch), and overlap is measured in time (seconds).

Lift and Timing

Next is the Lift and Timing. You cannot discuss camshaft without mentioning these two. Every car maker has their jargon to use for such technology. Honda uses VTEC; for Mitsubishi, they use MIVEC; in BMW, they use VANOS and many more. They are essential because they adjust the air coming into the engine according to the demand at different RPM and driving conditions. However, particularly lift, should be precise as possible as it can damage the piston and the valve if the maximum is breached.

Lobe Separation Angle

And last but not least is the Lobe Separation Angle which is also called a lobe centreline angle. It is the angle between the centerlines of both intake and exhaust lobes. Higher angle reduces overlap, which improves the quality of idling and intake vacuum. However, the excessive duration can dilute the power and torque; to compensate for that, a wider angle is used to allow it to breathe.

What are the Types of Camshafts?

Types of camshafts and their choice of adrenaline

There are two major types of camshafts: the flat tappet and roller; each one operates in parallel with a particular lifter or follower. Inside those categories, there are two options: solid or hydraulic.

Tappet Camshafts and Roller

Tappet camshafts operate with both solid and hydraulic flat tappets, also known as followers or lifters. Roller camshafts, however, work with solid and hydraulic roller lifters. So, their names were based on what they operate.

Hydraulic Flat Tappets

Hydraulic flat tappets were popular back in the 80s and eventually succeeded by the modern hydraulic roller arrangement in which passenger cars were equipped. Hydraulic flat tappets go well and fit the pair with hydraulic lifters. This kind of setup keeps the noise down for more extended periods; it is best to use this setup for street and mild race applications. Unfortunately, they are not designed for a full race.

Hydraulic Rollers

On the other hand, hydraulic rollers would go the same way as the hydraulic tappets with the lifters and has a wide array of profiles. However, with this kind of setup, the capabilities of your engine are limited, and its RPM range would be a maximum of 6,500. But under optimal conditions, it can go higher.

But, it comes with a price, literally as it is more expensive than the previous flat tappets. Mainly due to its method of production and the product that execute. It was made through precision-ground heat-treated tool steel and stainless steel components, polished DLC coatings to resist abrasion, pressure-fed oiling, and exacting tolerances.

Flat Tappet Camshaft

Even though mechanical flat tappet camshaft was replaced by the mechanical roller camshaft in 2015 as ruled by NASCAR, it is still used today and remained as one of the cornerstones of Circle Track racing and street performance engines due to its lightweight attribute and durability. It is made from tool steel, topped with DLC coating, and operated in alignment with a tool steel camshaft.

Roller Tappet Camshafts, Solid Fold Tappets, Solid Rollers

The ones who replaced the solid tappets were the roller tappet camshafts. These guys were used in aircraft radial engines in the 30s and are killing it on the V8 racing engine department, until this day, particularly in drag racing. This camshaft allows the smooth transition of seat times and permits stiffer valve springs to generate high engine speeds. Also, do note that both the solid fold tappet and solid roller require maintenance and need some periodic adjustments.

How Do I Choose the Right Camshaft?

Choosing the Right Camshaft for Your Performance Engine

Like everyday life, you make decisions, and that decision can either make or break you, depending on the weight of the situation. That also goes with choosing the right cam for the engine. There are two options for that, the OEM (Original Equipment Manufacturer) and the aftermarket ones. Stock replacement cams are a duplicate of the OEM, and its primary goal is to retain the engine's original performance, and it is the safest choice.

But if you aim for something more extensive, you can opt to buy cam profiles that are slightly enhanced or modified; that includes different cams for fuel economy, towing, and mild performance. Once you've already determined your preferred cam, the process proceeds as it becomes more complicated due to different specifics like the vehicle weight, drive gear ratio, transmission type kindred to the modification of the engine. They are parallel in terms of understanding the process.

Should You Buy the Flat Tappet or Roller Camshaft?

The answer to this question is solely inclined on the preferences you've made. But I want to present to you that if you plan to build a high-rev, high power, aggressive performance engine, a flat tappet cam with solid lifters is a lopsided choice as it can give you high-end RPM range without valve float. But, also consider that solid lifters are noisy, as we mentioned earlier, and require adjustments in incremental periods. To compare, roller cams with hydraulic lifters are a better option if you like to send your kid, nephew, or anyone on weekdays and hit the track on weekends as they make a good street performance engine and produce a lot of torque in the low RPM range.

What Camshaft is Best?

Some aftermarket brands where you can buy camshafts:

- COMP Cams

- Crane Cams

- Crower

- Edelbrock

- Erson Cams

- Ford Racing Performance Parts

- GM Performance Parts

- Greddy

- HKS

- Howards Cams

- Isky Racing Cams

- Lunati Cams

- Melling

- Mopar Performance

- Sealed Power from Federal-Mogul

What do Upgraded Camshafts do?

In sum, a camshaft is an integral and vital part of the internal combustion engine as it controls the valve, and even the slightest change that you do in the camshaft reflects on the machine's total performance. It is also the reason why racing becomes interesting, as the designing process of the cam requires a lot of effort, time, and years of expertise to produce. And with that, thousands of makers saturate to dominate the aftermarket cam industry to emerge as one of the best to do it. Deciding on the right camshaft ultimately depends on your engine goals.